Servo motor hexagon crimping machine for tubular cable lugs

Customer: Do you have a Automatic stripping machine for 2.5mm2 wire ? stripping length is 10mm .

SANAO: Yes , Let me introduce our SA-206F4 For you ,Processing wire range: 0.1-4mm², SA-206F4 is a small Automatic cable stripping machine for wire,It’s adopted Four wheel feeding and English display that it’s more Easier to operate than the keypad model, SA-206F4 can process 2 wire at one time ,It’s Greatly Improved stripping speed and save labor cost.Widely used in wire harness,Suitable for cutting and stripping electronic wires,PVC cables, Teflon cables, Silicone cables, glass fiber cables etc.

The machine is fully electric, and the stripping and cutting action are driven by stepping motor,not need additional air supply . However, we considering that the waste insulation may fall onto the blade and affect the working accuracy. So we think It is necessary to add an air blowing function next to the blades, which can automatically clean the blades’s waste when connected to the air supply,This greatly improves the stripping effect.

Advantage:

1. Bilingual LCD screen display: bilingual display in Chinese and English, automatic computer program design, simple and clear operations,Our machine have 99 kinds of programs, It can be set according to different stripping requirements, Meet customers’ various stripping requirements.

2. Many kinds of processing methods: One-time completion of automatic cutting, half stripping, full stripping, multi-section stripping.

3.Double-wire process: Two cable processed at the same time;It’s Greatly Improved stripping speed and save labor cost .

3. Motor: Copper core stepper motor with high precision, low noise, precise current which controls motor heating well, longer service life.

4. Pressing line adjustment of wire feeding wheel: tightness of the pressing line at both wire head and wire tail can all be adjusted; adapt to wires of various sizes.

5. High quality blade: High-quality raw materials with no burr free incision are durable, wear-resistant and have a longer service life.

6. Four-wheel driving: Four-wheel driven stable wire feeding; adjustable line pressure; high wire feeding precision; no damage and to pressure to wires.

| Model | SA-206F4 | SA-206F2.5 |

| Cutting length | 1mm-99999mm | 1mm-99999mm |

| Peeling length | Head 0.1-25mm Tail 0.1-100mm (According to the wire) | Head 0.1-25mm Tail 0.1-80mm (According to the wire) |

| Applicable wire core area | 0.1-4mm² (process 1 wire) 0.1-2.5mm² (process 2 wire) | 0.1-2.5mm² (process 1 wire) 0.1-1.5mm² (process 2 wire) |

| Productivity | 3000-8000pcs/h(according to the cutting length) | 3000-8000pcs/h(according to the cutting length) |

| Cutting Tolerance | 0.002*L·MM | 0.002*L·MM |

| Outer diameter of catheter | 3,4, 5 ,6 MM | 3,4, 5MM |

| Drive mode | Four wheel Drive | Four wheel Drive |

| Stripping Mode | Long wire/ short wire /Multi-stripping / multi stripping | Long wire/ short wire /Multi-stripping / multi stripping |

| Dimension | 400*300*330mm | 400*300*330mm |

| Weight | 27kg | 25kg |

| Display method | Chinese or English interface display | Chinese or English interface display |

| Power supply | AC220/250V/50/60HZ | AC220/250V/50/60HZ |

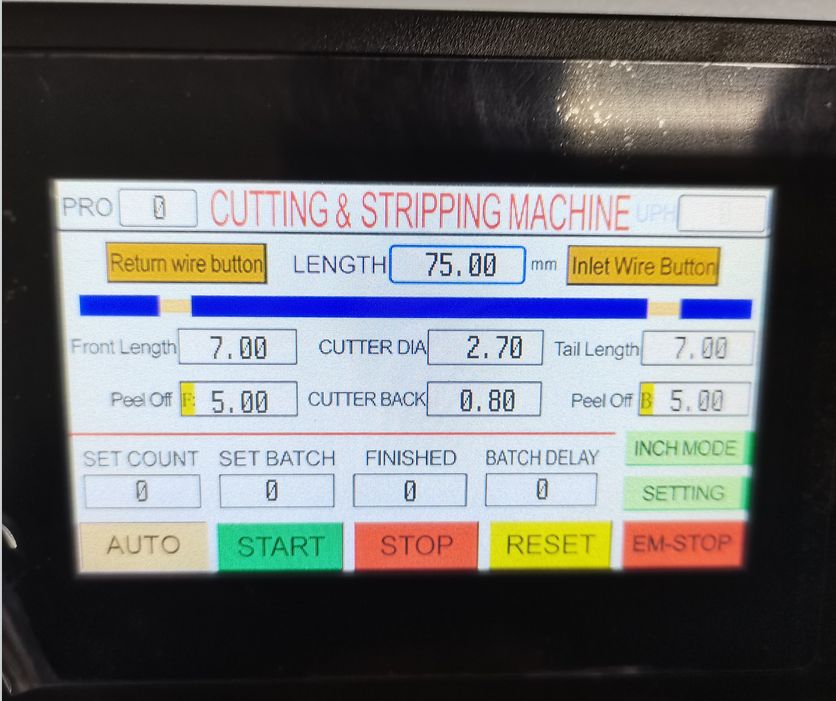

Machine paramater setting is very ,Full English color display .

For example: Cutting length is 75MM , Setting Full length is 75MM

Outer

Stip L: Outer strip length is 7MM . When 0 is set, there is no stripping action.

Full stripping: Pull –off >Strip L is , For example 9>7

Half stripping: Pull –off <Strip L is Half stripping , For example 7<5

Outer blades value: Generally less wire outer diameter, For example wire diameter is 3mm, The data is setting 2.7MM

After seeing our setting is very simple, do you want one ? Welcome to inquire.