Introduction to the characteristics and uses of the lead wire prefeeder

The machine has unique features and a wide range of uses, making an important contribution to improving production efficiency and quality. The lead prefeeder is a precision mechanical device, mainly used to quickly and accurately feed metal wires into the target interface during the manufacturing process of electronic components. The machine adopts advanced technology and control system to ensure the accurate positioning and precise feeding of the wire.

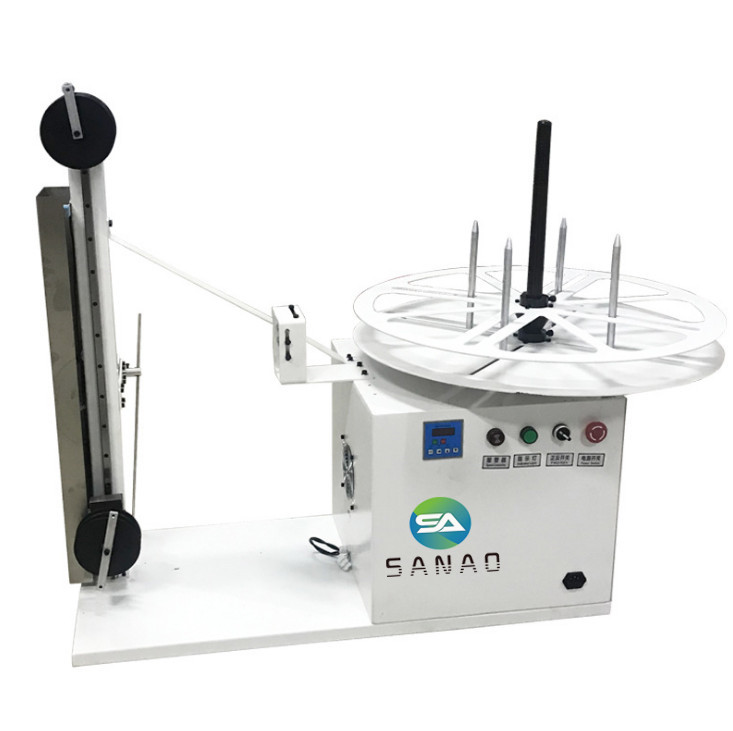

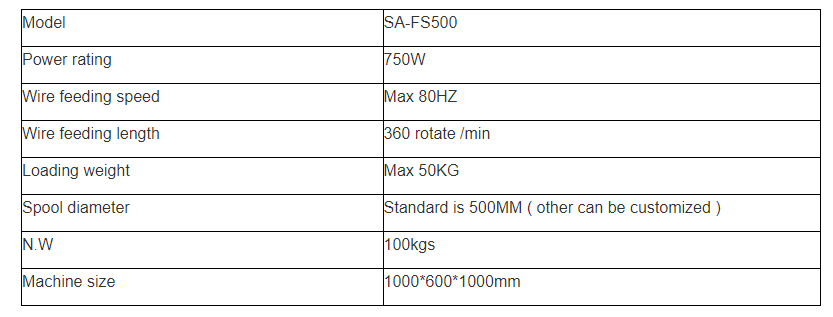

Our prefeeding machine SA-FS500 is a highly dynamic prefeeding machine, which has been developed to feed cable and wire gently to automatic machines or other wire harness process machinery. Due to the horizontal structure and pulley block design , this prefeeder works very stable and has large wire accumulation capacity.

Features:

1.The frequency converter controls the pre-feeding speed. It is suitable for various wires and cables.

2.can cooperate with any kind of automatic machine to feed the wire. Can Automatically cooperate with wire stripping machine speed

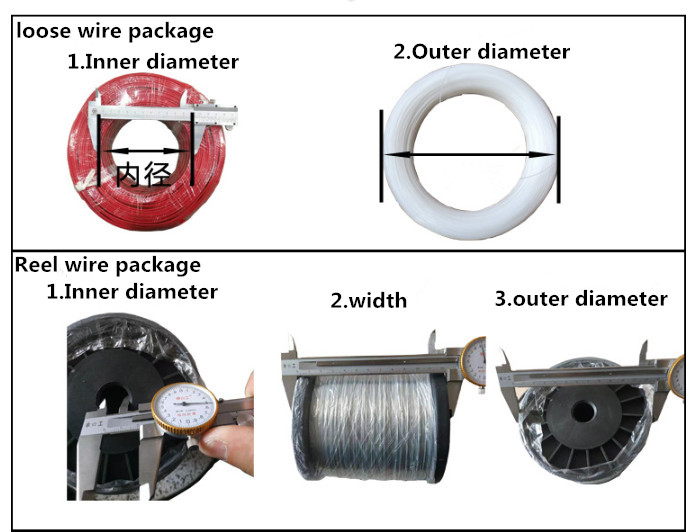

3.Applicable to various types of electronic wires, cables, sheathed wires, steel wires, etc.

4. Max Load weight: 50KG

Its characteristics include the following aspects: High Speed and Precise: The wire pre-feeder has excellent running performance, which can realize high-speed continuous feeding, and the speed can reach thousands of times per minute. At the same time, it has a high-precision control system, which can ensure the precise feeding and placement of the wire. High degree of automation: The wire pre-feeding machine adopts a fully automatic design, and through advanced control systems and sensors, it can realize automatic wire feeding, positioning and cutting. This not only improves work efficiency, but also reduces human error and fatigue.

Its main uses include the following aspects: Wire assembly: The wire pre-feeder can quickly and accurately feed metal wires into the lead holes of electronic equipment, improving assembly efficiency and quality. Wire and cable manufacturing: Lead pre-feeders are also widely used in the wire and cable manufacturing process to help improve production efficiency and product quality.

According to industry experts, with the development of the electronics manufacturing industry and the increasing demand for high-efficiency production, the market demand for lead pre-feeders will further expand. At the same time, with the continuous advancement of technology, the performance of the lead pre-feeder will be further improved and optimized in the future, bringing greater development opportunities for the electronics manufacturing industry.