Features and uses of wire harness labeling machine

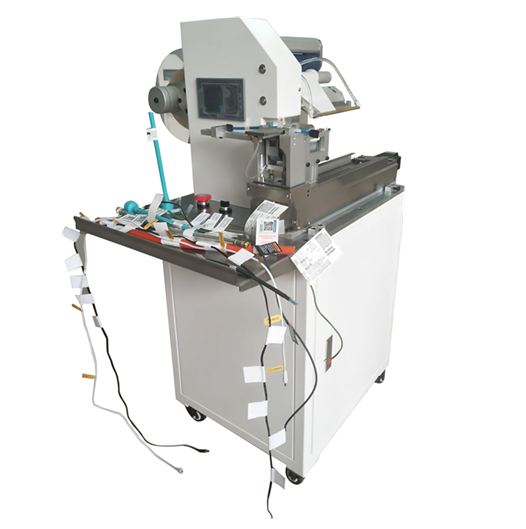

Recently, the wire harness labeling machine has attracted much attention and has become an important equipment in the electrical equipment manufacturing industry. With unique features and wide applications, the machine has made an important contribution to improving production efficiency and product quality. SA-L30. Automatic wire labeling machine ,Design for Wire Harness Flag Labeling Machine, Machine have two labeling method , One is Foot switch start , The other is Induction start .Directly put wire on machine , Machine will labeling automatically . Labeling is Fast and accurate.

Advantages:

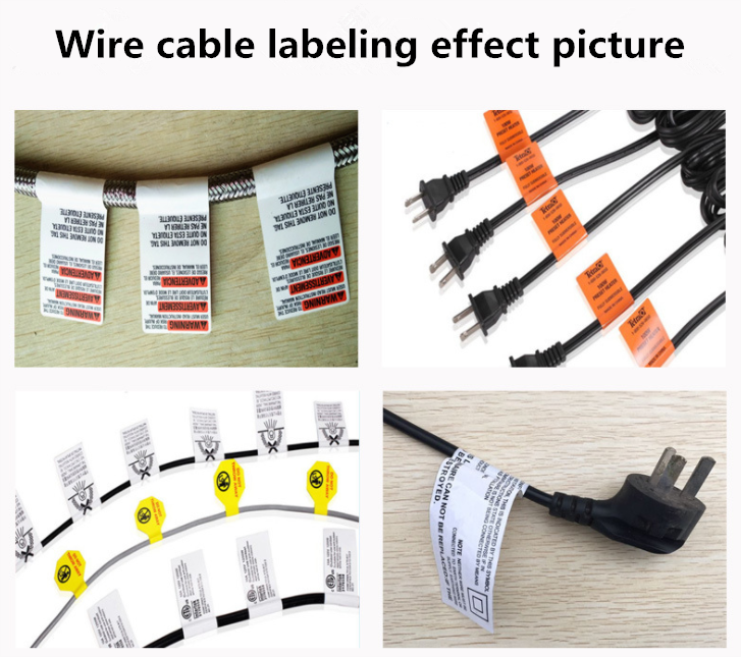

1.Widely used in wire harness,tube ,mechanical and electrical industries

2.Wide range of applications, suitable for labeling products of different specifications

3.Easy to use, wide adjustment range, can label products of different specification

4.High stability, advanced electronic control system consisting of Panasonic PLC + Germany label electric eye, support 7×24-hour operation.

Its characteristics mainly include the following aspects:

High-precision positioning: The wire harness labeling machine is equipped with advanced sensors and precision control systems, which can meet the high-precision requirements for precise positioning of the lead wire bundle and labeling.

Fast and efficient: The machine has the ability of high-speed attachment, and can complete the label attachment of large quantities of lead wire bundles in a short time, greatly improving production efficiency.

Flexible and adjustable: the wire bundle labeling machine can be flexibly adjusted according to different specifications and sizes of wire bundles to meet different production needs. At the same time, you can also set a variety of label attachment modes to meet different application scenarios.

Lead harness labeling machines are widely used in the electrical equipment manufacturing industry. The main uses include the following aspects: Product identification: By attaching labels to lead wire bundles, rapid identification and classification of products can be achieved. This is of great significance for subsequent assembly, repair and traceability work. Process management: Using the wire harness labeling machine, the process information label can be added to the lead wire harness during the manufacturing process to help process management and quality control. After-sales service: The label on the lead wire harness can contain after-sales service information, such as technical support telephone number and maintenance address, etc., which is convenient for users to inquire and contact during daily maintenance and use.

With the continuous innovation and application of technology, the function and performance of the lead wire harness labeling machine will be further improved, providing strong support for the innovation and development of the electrical equipment manufacturing industry.