- Home

- News

- Automatic Terminal Cross Section Analysis System: A new tool to assist quality control in the electronics industry

Automatic Terminal Cross Section Analysis System: A new tool to assist quality control in the electronics industry

Automatic Terminal Cross Section Analysis System has recently attracted widespread attention in the electronics industry. The development of the modern electronics industry is inseparable from the application of electrical connectors, and the quality of connectors is directly related to the stability and performance of the equipment. However, traditional terminal cross-section analysis methods usually need to be performed manually, which is cumbersome, time-consuming and error-prone. To solve this problem, the Automatic Terminal Cross Section Analysis System came into being.

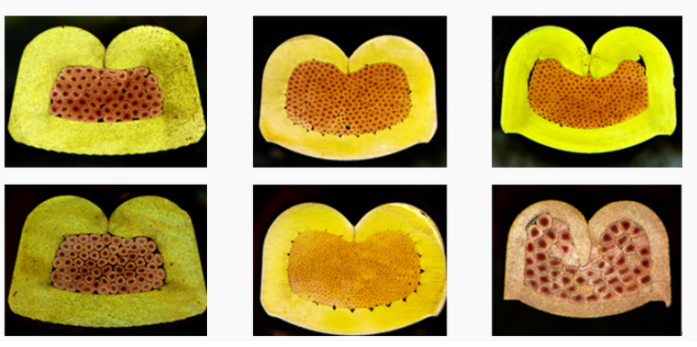

Model :SA-TZ4 Description: The terminal cross-section analyzer is designed to detect the quality of crimping terminal, it includes the following modulesterminal fixture, cutting and grinding corrosion cleaning. cross-section image acquisition, measurement and data analysis.enerate data reports. It only takes about 5 minutes to complete the cross- section analysis of a terminal

This system combines terminal samples with high-resolution cameras and uses image analysis algorithms to automatically detect and analyze terminal sections, replacing traditional manual sectioning and microscopic observation. Its main uses include quality inspection of various connectors in the electronics industry, reference for process improvement, and research and development of electronic components.

The system has the following salient features: Automation: Through automatic scanning and image analysis, the system can quickly and efficiently complete the analysis of terminal cross-sections, greatly improving work efficiency and accuracy and reducing errors in manual operations.

High precision: This system uses high-resolution cameras and advanced image analysis algorithms to accurately measure key parameters such as size, shape and defects of terminal cross-sections, providing a reliable basis for quality control. Multifunctional: In addition to terminal cross-section analysis, the system can also perform functions such as terminal conductivity testing, withstand voltage testing and temperature change testing, further improving the evaluation and monitoring of connector quality.

The advent of the Automatic Terminal Cross Section Analysis System marks a big step forward in the field of quality control in the electronics industry. Its use will greatly improve the efficiency and accuracy of quality inspection of electronic connectors, reduce the shipment rate of defective products, and improve the reliability and performance of equipment.

Looking to the future, with the rapid development of the electronics industry, automatic terminal cross-section analysis systems are expected to become standard equipment in the industry. In short, the launch of the Automatic Terminal Cross Section Analysis System provides the electronics industry with a new, efficient and accurate quality control method, which will inject new vitality and power into the development of the electronics industry.