Automated Tape Cutting Machine: A Breakthrough in Precision and Efficiency

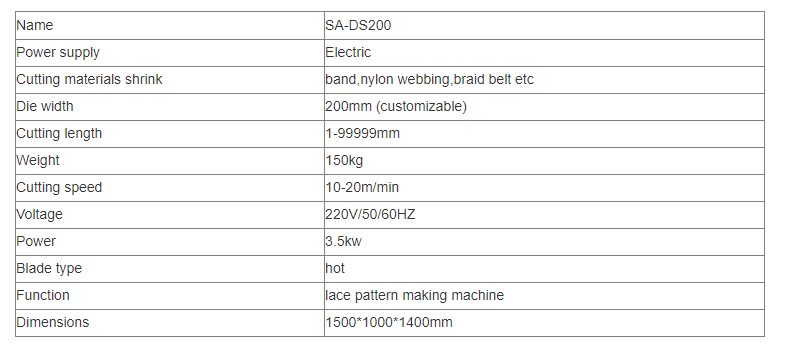

This advanced machine boasts unique features and versatile applications, revolutionizing productivity and product quality.The Automatic Different Shape Tape Cutting Machine is a highly efficient mechanical device designed to accurately cut and shape various types of tapes. Equipped with cutting-edge technology and control systems, this machine ensures precise cutting and shaping while increasing efficiency.

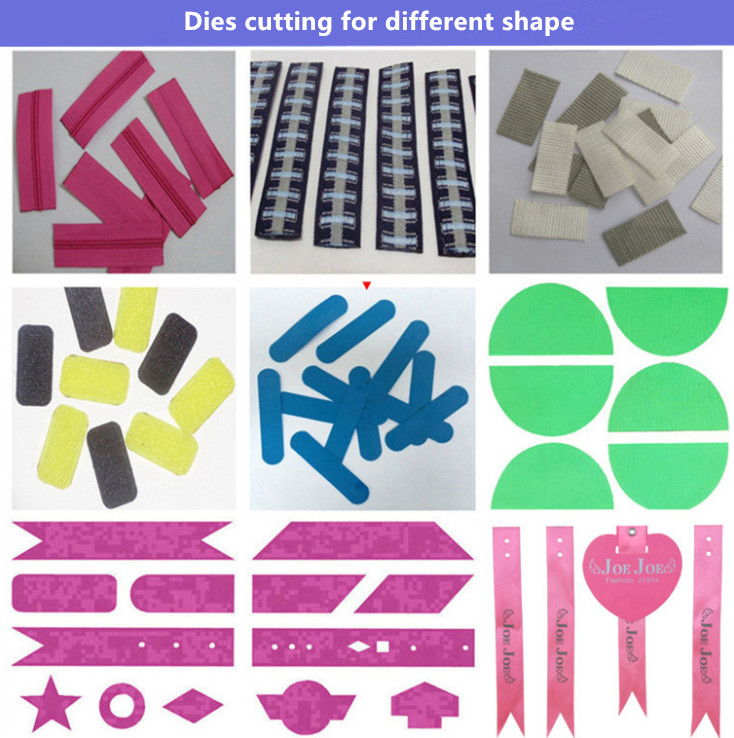

Automatic Woven Fabric Tape Cutting Machine in Various Shape, Adopt dies cutting, different cutting shape different cutting dies,the cutting length is fixed for each dies , the machine can proceed material cutting automatically. Cutting speed can be set according to different materials.

Suitable cutting material:

Hot belt: Color belt, textile belt, ribbon, nylon belt, safety belt, backpack belt, elastic band, thread belt etc.

Braided belt, nylon webbing, colored satin, rubber bone, zipper, etc.

Advantage :

1. Adopts Adopt mold cutting, Different cutting shape different mold , Can cut out any desired shape.

2. Mold cutting High cutting precision and High speed cutting .

3. Machine very easy to operate , Just change the cutting mold and adjust cutting speed .

4. It is mostly used for cutting gift belts, Velcro, foam, leather, etc.

Key features of this machine include:

High Precision and Accuracy: The machine is equipped with state-of-the-art sensors and a precision control system, ensuring accurate cutting and shaping of tapes according to specific requirements.

Quick and Efficient: The machine is capable of high-speed cutting and shaping, significantly reducing production time for a large volume of tapes, leading to increased productivity.

Versatility and Customization: The Automatic Different Shape Tape Cutting Machine can be customized to accommodate different sizes and shapes of tapes, catering to various manufacturing needs. Additionally, it offers adjustable settings for different cutting and shaping patterns, meeting diverse application requirements.

With continuous technological advancements in tape cutting and shaping processes, this machine is expected to support innovation and development across various manufacturing sectors.